CSL DD metal QR clank, pop, etc fix. No more tape or zip ties needed

Fanatec take note that an O-ring should be included with the retaining bolt or a bolt redesign with a larger head/washer built in.

Tired of tape gumming up and having to reapply? Don't want to mess around with a zip tie and getting it aligned?

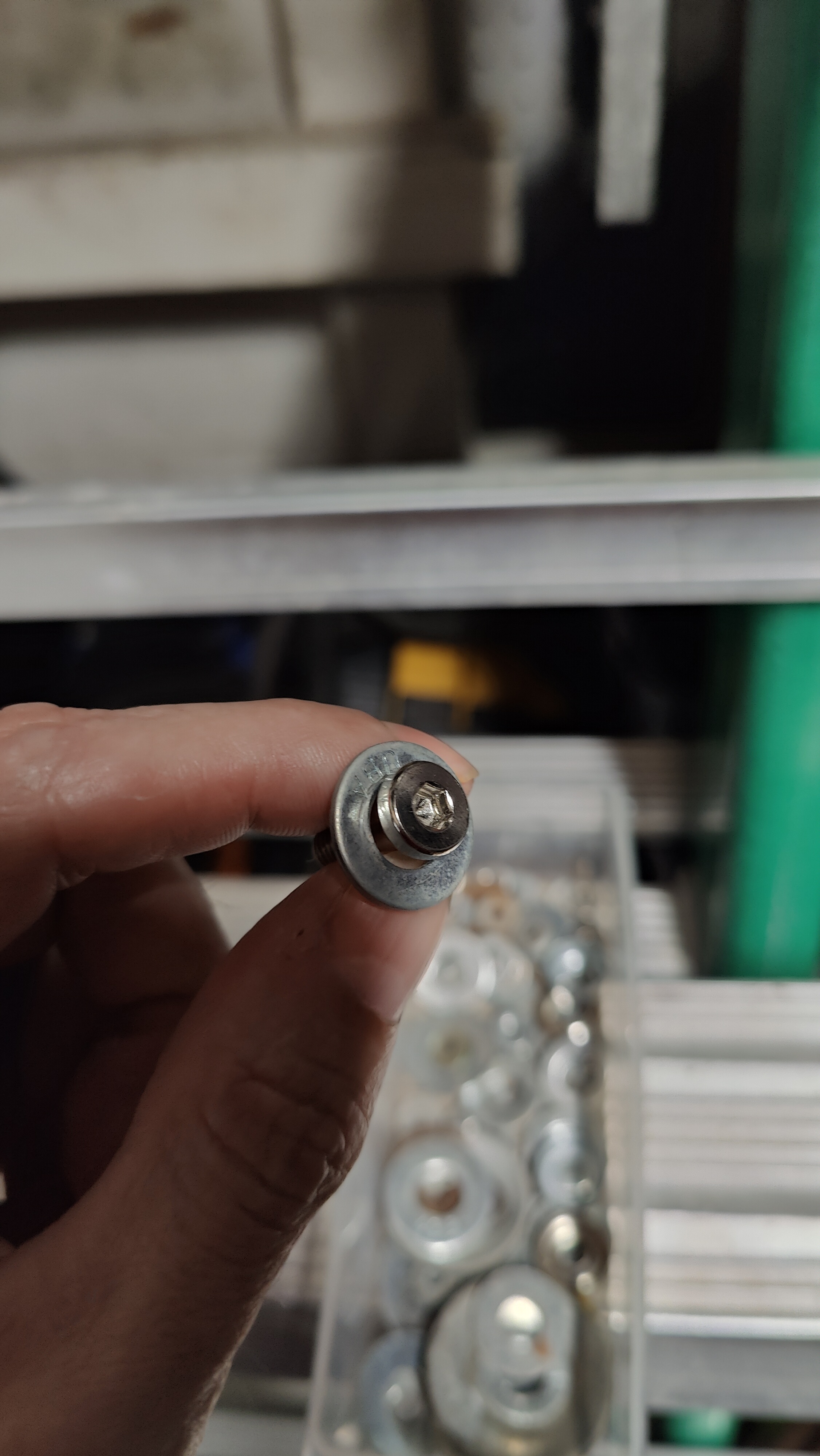

Head to your neighborhood parts store and ask for the o-ring tray or just grab a package of assorted o-rings although you only need one. Slide that puppy over the head of your retaining bolt and install the bolt as usual. No more mess, no more reapplying tape, etc. The o-ring stays on the bolt when you remove it.

The inner diameter is just large enough for the shaft and the outer diameter is just a bit bigger then the head on the bolt. For thickness it's a tad shorter then the head. More like the thickness of the tapered part further down the bolt.

I also just tried a metal washer. It has to fit over the taper but be smaller inner diameter then the head and the outer diameter can only be so large or the QR collar becomes an issue and is in the way.

Comments

the concept of quick release is lost with that screw.

we need a real solid product, and then it is truly called a quick release.

I could see them putting in a stronger spring inside the collar to hold the collar more stationary and possibly avoid the need for the bolt.

A stronger spring would be useless, the problem is another.

This is a CSW 2.5 wheelbase.

Do you notice any hub differences compared to our CSLDD and DD Pro?

These are parts with industrial tolerances, quite cheap. Always keep in mind, that every QR has to mate with every wheelbase, and it has to be relatively cheap, so tolerances can't be too tight.

Impossible to expect precise couplings, the solidity of the coupling is obtained by forcefully pushing one piece onto the other.

The only spring inside the QR1 is used only to push the ring nut to close. It does not produce any force on the Wheelbase hub. It is only used to open and close the spheres.

What forces the QR1 onto the hub are simple rubber O-rings.

Inside the QR1 there is a rubber oring, which forces the coupling with the hub.

In the hub of CSW 2.5 and CSL Elite, there is a recess with an oring, which locks the inner boss of the QR1 on the hub.

There are 2 rubber orings that lock the 2 parts together, and at the same time dampen any possible contact and noise. A conical screw has been foreseen when the tolerances are extremely unfavourable. On DD1 and DD2 which produce higher forces there is a rubber ring loaded by a screw nut, to obtain a greater grip.

But now, for some unknown reason, our CSL DDs don't have the oring on the hub.